6___________________

Flat-Plate

Collectors

Flat-plate collectors are in wide use for domestic household hot-water heating and for space heating, where the demand temperature is low. Many excellent models of flat-plate collectors are available commercially to the solar designer. A discussion of flat-plate collectors is included here because of their use in industrial systems either to supply low-temperature demands or to preheat the heat transfer fluid before entering a field of higher-temperature concentrating, collectors. Detailed descriptions of flat-plate collector design, performance and system design using these collectors may be found in the following sources: Duffie and Beckman (1980), Lunde (1980), and Kreider and Kreith (1982). The interested reader is referred to these for further information.

The emphasis of this chapter is to develop an understanding of both the attributes of different design features and the performance characteristics of this class of collector. This understanding will permit the system designer to evaluate whether flat-plate collectors should be considered in a system design. Also, the information required to select an appropriate commercial unit is presented here.

This development will follow the outline below:

The construction of a flat-plate collector is shown in Figure 6. 1. The basic parts noted are a full-aperture absorber, transparent or translucent cover sheets, and an insulated box. The absorber is usually a sheet of high-thermal-conductivity metal with tubes or ducts either integral or attached. Its surface is painted or coated to maximize radiant energy absorption and in some cases to minimize radiant emission. The cover sheets, called glazing, let sunlight pass through to the absorber but insulate the space above the absorber to prohibit cool air from flowing into this space. The insulated box provides structure and sealing and reduces heat loss from the back or sides of the collector.

Figure 6.1 A typical liquid flat-plate collector.

The main element of a flat-plate collector is the absorber plate. It covers the full aperture area of the collector and must perform three functions: absorb the maximum possible amount of solar irradiance, conduct this heat into the working fluid at a minimum temperature difference, and lose a minimum amount of heat back to the surroundings.

Absorption. Solar irradiance passing through the glazing is absorbed directly on the absorber plate without intermediate reflection as in concentrating collectors. Surface coatings that have a high absorptance for short-wavelength (visible) light, are used on the absorber. Usually these coatings appear dull or "flat," indicating that they will absorb radiation coming from all directions equally well. Either paint or plating is used, and the resulting black surface will typically absorb over 95 percent of the incident solar radiation.

Fin Heat Removal. The second function of the absorber plate is to transfer the absorbed energy into a heat-transfer fluid at a minimum temperature difference. This is normally done by conducting the absorbed heat to tubes or ducts that contain the heat-transfer fluid. The heat-transfer fluid may either be a liquid (water or water with antifreeze) or gas (air). The important design criterion here is to provide sufficient heat transfer capability that the difference between the temperature of the absorber surface and the working fluid is not excessive; otherwise, the heat loss from the absorber would be excessive. High heat-transfer rates are usually accomplished at the expense of pumping power and absorber plate material.

When a liquid is used as the heat-transfer fluid as is most often the case, special problems occur in transferring the heat absorbed on the absorber surface into the fluid. Liquid collector absorber plates often consist of a flat sheet of metal with tubes spaced 10-25 cm (4-10 in.) apart and attached to it in some fashion (integral, brazed or press fitted). The sheet of metal absorbs most of the solar irradiance and acts as a fin to bring the absorbed heat into the fluid. The following are important points in designing a good ‘tube and sheet’ absorber:

When air is the heat-transfer fluid, often the back side of the absorber plate usually forms one surface of a duct and heat is transferred through the absorber sheet to the air over the entire back surface of the absorber. A thin, rather than thick, absorber sheet of high-thermal-conductivity material will enhance this heat-transfer process. The internal air passage must be designed to provide a sufficiently high airflow velocity past the back of the absorber to give adequate heat transfer without producing a high pressure drop across the collector. Low heat-transfer rates cause the absorber plate to become significantly hotter than the heat-transfer fluid, which increases heat loss. On the other hand, a large pressure drop across the collector causes high pumping power consumption by the fans supplying the air.

Emittance. Because the temperature of the absorber surface is above ambient temperature, the surface re-radiates some of the heat it has absorbed back to the surroundings. This loss mechanism is a function of the emittance of the surface for low-temperature, long-wavelength (infrared) radiation. The dilemma is that many coatings that enhance the absorption of sunlight (short-wavelength radiation) also enhance the long wavelength radiation loss from the surface. This is true for most dull black paints.

A class of coatings, mostly produced by metallic plating processes, will produce an absorber surface that is a good absorber of short-wavelength solar irradiance but a poor emitter of long-wavelength radiant energy. The function of these coatings, called selective surfaces, was described in detail in Chapter 5. Flat-plate absorbers that have selective surfaces typically lose less heat when operating at high temperature, as will be seen in Section 6.3.3. However, the absorptance of selective coatings is seldom as high as for non-selective coatings, and a tradeoff must be made based on whether the increased high-temperature performance overshadows the reduced low-temperature performance and expense of the selective coating.

The absorber is usually covered with one or more transparent or translucent cover sheets to reduce convective heat loss. In the absence of a cover sheet, heat is lost from the absorber as a result of not only forced convection caused by local wind, but also natural convective air currents created because the absorber is hotter than ambient air. The cover sheet forms a trapped air space above the absorber, thereby reducing these losses. However, convective loss is not completely eliminated because a convective current is set up between the absorber and the cover sheet, transferring heat from the absorber to the cover sheet. External convection then cools the cover sheet, producing a net heat loss from the absorber. In addition, heat loss is reduced because of the thermal resistance of the added air space.

Number of Covers. The number of cover sheets on commercial flat-plate collectors varies from none to three or more. Collectors with no cover sheet have high efficiencies when operated at temperatures very near ambient temperature. This is because incoming energy is not lost by absorption or reflection by the cover sheet. When no cover sheet is used, however, a considerable amount of the incident energy is lost during operation at temperatures much above ambient or at low solar irradiance levels. A typical application for an uncovered flat-plate collector is for swimming pool heating, where temperatures less than 10ºC (18ºF) above ambient are required.

Increases in the number of cover-sheets increases the temperature at which the collector can operate (or permits a given temperature to be reached at lower solar irradiance). One or two cover sheets are common, but triple glazed collectors have been designed for extreme climates. In addition to the added expense, each added cover sheet increases the collection efficiency at high temperature by reducing convection loss but decreases the efficiency at low temperatures because of the added absorption and reflectance of the cover.

In regions of average mid-latitude temperatures and solar radiation, collectors with no glazing are generally used for applications to 32ºC (90ºF), single-glazed collectors are used for applications to 70ºC (158º F), and double-glazing is used in applications above 70ºC (158ºF). As discussed in Chapter 5, collector efficiency increases with increasing solar irradiance level but decreases with increasing operating temperature. In regions of low average solar irradiance or extremely low temperatures, therefore, double-glazed collectors are used in applications where single-glazed collectors should be used normally and single-glazed collectors for unglazed applications. Also, selective absorber surfaces become more worthwhile.

Materials. Because of its superior resistance to the environment, glass is used as the outer cover sheet on most commercial collectors. Usually the glass is tempered, with a low iron content and 3.2-6.4 mm (0.12-0.25 in.) thick. The surface may be either smooth, making the glass transparent, or with a surface pattern, making it translucent. Both types have a transmittance of around 90 per cent.

Plastic cover sheets are sometimes used for the second cover sheet when two sheets are required. Installation of the plastic sheet beneath the glass protects the plastic from the environment. Glass also does not transmit UV radiation and thus protects the plastic, which is usually sensitive to this portion of the solar spectrum. Rigid sheets of acrylic-or fiberglass-reinforced polymers are in use, as are stretched films of polyvinyl fluoride. Some of these plastic cover sheets have a transmittance approaching that of low iron glass. A major draw back of this scheme is the potential for overheating the plastic sheet at collector stagnation (no-flow) temperatures.

Flat-plate collectors will absorb energy coming from all directions above the absorber (both beam and diffuse solar irradiance). Because of this characteristic, flat-plate collectors do not need to track the sun. They receive more solar energy than a similarly oriented concentrating collector, but when not tracked, have greater cosine losses.

Since tracking is not required, flat-plate collectors may be firmly fixed to a mounting structure, and rigid plumbing may be used to connect the collectors to the remainder of the system. Moving structure, motors, and tracking control systems are eliminated, thereby reducing the complexity of the system. As discussed in Chapter 5, however, because of the cosine effect, less total energy falls on a fixed surface over the period of a day than on a surface that tracks the sun about one or two axes.

In order to increase their output, flat-plate collectors may be repositioned at intervals or placed on a single- or two-axis tracking mechanism. Either of these options increases the output of the collector but eliminates the advantage of fixed piping and mounting structure.

6.2.2 Diffuse Solar Radiation Utilization

A flat-plate collector absorbs both the direct and the diffuse components of solar radiation. This partially compensates for the fact that fixed surfaces receive less energy because of the cosine effect. Although the diffuse solar irradiance is only about 10 percent of the direct normal solar irradiance on a clear day, on a cloudy day almost all of the available solar irradiance is diffuse.

A comparison between the energy falling on a fixed and a fully tracking flat-plate collector and on a fully tracking concentrating collector is shown in Table 6.1. The data are yearly average values taken from SERI (1981b). The comparison is location dependent because of the latitude effects on the incidence angle and the difference in cloud cover.

Table 6.1. Collectible Solar Radiation Comparison Between

Flat-Plate and Concentrating Collectors

|

Annual Average Daily Solar Radiation (MJ/m2) |

|||

|

Collector |

Albuquerque |

Madison |

|

|

Two-axis tracking flat-plate collector |

31 |

19.5 |

|

|

Fixed, latitude-tilt flat-plate collector (direct plus diffuse) |

23 |

15 |

|

|

Two-axis tracking concentrator |

26.5 |

14 |

|

For both locations, the two-axis tracking flat-plate collector receives more energy. However, in the dry, high desert climate of Albuquerque, a fixed flat-plate collector loses more energy from the cosine effect than it gains by being able to collect diffuse energy. In the Midwestern climate of Madison, Wisconsin, the energy lost by fixing the flat-plate collector approximately equals that gained over a concentrator by its ability to collect the diffuse component of solar irradiance. It should be noted that Table 6.1 only indicates the relative amounts of energy available for collection. The choice of collector type or whether to track a flat-plate collector is generally based on system cost and energy output rather than energy input.

Currently, flat-plate collectors cost less than concentrating collectors. Part of reason is the lack of need for a complex tracking system. However, part of the reason is because many more flat-plate than concentrating collectors are being produced today. At large production rates, however, it is still not clear whether it is less expensive to cover an aperture area with an absorber plate or with reflective material.

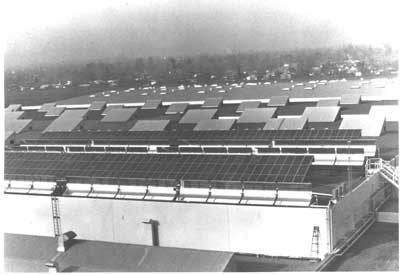

Because of their potential to produce more low-temperature energy for a given cost, flat-plate collectors have been considered for use as pre-heaters for concentrating collectors in high-temperature industrial process heat systems. The major prototype of this system configuration is at Campbell Soup Company in Sacramento, California and is shown in Figure 6.2. The decision of whether to include flat -plate collectors as pre-heaters ultimately is based on the balance between performance and cost.

Figure 6.2 The Campbell Soup Company industrial process heat installation in Sacramento, CA. Flat-plate collectors are used to preheat water before entering the parabolic trough concentrators.

Courtesy of Sandia National Laboratories.The orientation of a flat-plate collector is a concern in system design. The designer must decide on both the collector azimuth and tilt angles or to install the collectors horizontally.

Azimuth. The most obvious azimuth for a fixed surface in the northern hemisphere is south facing. This will give equal amounts of energy before and after noon and usually the maximum daily total energy collected. There are a number of reasons why the system designer may not select this azimuth. It may be simply that the building or land orientation makes it desirable to rotate the azimuth axis to fit the installation conditions. Other performance related factors can affect the collector field orientation.

If the industrial demand is greater in the morning and there is no overnight thermal storage in the system , the azimuth may be rotated to the east. This would make the peak energy collection occur earlier in the morning but give a slightly lower daily total. A similar westerly rotation would provide more after noon energy if desired.

Another factor causing the collectors not to be oriented toward the south is the presence of a blockage (mountain or building) that shades morning or after noon sunlight. In this case the optimum orientation may call for rotation away from the blockage. Likewise, either persistent morning or afternoon cloud cover may cause the designer to orient the field azimuth for optimum energy collection.

It is generally accepted that the azimuth of a fixed field may be rotated up to 15 degrees from south and not make a significant difference in .the overall energy collection. With the information presented in Chapters 2 through 4, however, a simple average cloudy-day model can be easily coded and a comparison made between design alternatives.

Tilt. The most logical tilt angle for the fixed flat-plate collector is to tilt the surface from horizontal by an angle equal to the latitude angle. At this tilt, if the collector is facing south, the sun will be normal to the collector at noon twice a year (at the equinoxes). Also, the noontime sun will only vary above and below this position by a maximum angle of 23.5 degrees.

However, there are some system design considerations that may encourage the designer to tilt the collector’s above or below this angle. For instance, if the slope of the roof where the collectors are to be installed is within 15 degrees of the latitude tilt, one would probably choose a flush roof mounting. If the demand is greater in the winter months as with space heating, the designer may choose to tilt the collectors toward the horizon more and accept the summer energy loss. Similarly, the reverse may be true for a heavy summer demand (i.e., cooling).

As with collector azimuth orientation, shadowing objects may be considered and the collector tilted less because of blockage of solar irradiance when the altitude of the sun is low. Another factor that may affect the tilt orientation is the climate. If the particular region has considerable cloud cover during the winter, the collectors would be tilted to maximize summer energy collection. One final factor that could influence the approximate tilting of the collector is the systems operating threshold. If the system needs a high value of solar irradiance to begin operation, tilting the collectors closer to vertical may provide more energy to the system during start-up.

Again, in order to predict these effects, an analysis should be made using solar radiation data and sun angle computations to predict the exact effects of a particular set of circumstances

The yearly average data for two sites are shown on Figure 6.3. Plots for the other sites would be similar. Note that for both sites shown, the maximum yearly irradiation is obtained by surfaces tilted slightly less than the latitude angle. This is because of the greater cloud cover in the winter for both sites. Also note that a wide variation in tilt angle makes little difference in the irradiation received. This implies that the collector tilt optimization is not critical and that even horizontal surfaces may be an appropriate design choice if the cost of installation is considerably less for this orientation.

Figure 6.3 Total (global) irradiation on a south-facing tilted surface. Average ground reflectance was assumed to be 0.20

The energy collection efficiency is normally determined by testing. As discussed in Chapter 5, collector performance test data are correlated with a parameter comprised of the collector temperature rise above ambient divided by the solar irradiance. For flat-plate collector performance, the collector temperature and the solar irradiance used in this correlation are different from those used for concentrating collectors.

The collector temperature used for flat-plate collector performance correlation is normally the temperature of the heat-transfer fluid entering the collector, not the average fluid temperature, as is common for concentrating collectors.

Although the use of fluid inlet temperature makes application of the performance correlation easier in design studies, it also makes the correlation considerably more dependent on the flow rate of the heat-transfer fluid. Therefore, every correlation using fluid inlet temperature must specify the fluid flow rate at which the measurements were made. Deviation from this flow in a particular design requires that a different correlation be used. The recommended test flow rate (ASHRAE, 1977) for a liquid collector is 0.02 kg/hr (14.7 lb/hr ft2) and for an air collector, 0.01 m3/s m2 (1.97 cfm/ft2) at atmospheric pressure.

Because a flat-plate collector can collect both beam (direct) and diffuse solar radiation, the global (total) solar irradiance is used as the basis for flat-plate collector performance correlations. In testing the collector, the aperture irradiance is the global (total) solar irradiance measured in the plane of the collector, which includes the cosine loss of the beam component and some ground reflection if the collector is tilted from the horizontal as is usually the case.

A dilemma arises with the use of this performance correlation because the global (total) solar irradiance on a tilted aperture It,a is used as input into the correlation. This value must include ground reflection. Equation (4.6) gives the designer a means of predicting the global (total) aperture irradiance when the aperture is tilted from the horizontal by an angle .

The appropriate collector performance correlation for a flat-plate collector is Equation (5.7) modified for a non-concentrating collector:

where the optical efficiency and the overall heat loss coefficient UL were discussed in Chapter 5, and the total aperture irradiance It,a in Chapter 4, Equation 4.29. The term FR is the collector heat removal efficiency factor and is dependent on the absorber plate tube spacing and the flow rate of heat transfer fluid through these tubes. The analytical development of this factor is described in Duffie and Beckman (1980).

Figure 6.4 gives typical performance for a number of different types of flat-plate collectors. These range from an unglazed absorber as is used for very low temperature applications to double-glazed, selective-surface collectors. Also included on this plot is an evacuated tube-type collector, which is discussed in the following paragraphs.

Figure 6.4 Performance of typical commercial flat-plate solar collectors.

A second abscissa scale has been included on this plot to aid in rapid interpretation. Since the abscissa is the temperature difference divided by the total solar irradiance, these parameters may be separated in nomogram style with a separate abscissa.

Although flat-plate collectors may be operated at fairly high temperatures when solar irradiance or ambient temperature is high, as solar irradiance or ambient temperature decreases or the angle of incidence increases, the efficiency falls. An example is shown in Figure 6.4 for a temperature difference of 50ºC (90ºF), where the solar irradiance has decreased to 600 W/m2 (190 Btu/hr ft2), and the efficiencies of the first three collectors have dropped below usable levels. This curve supports the conclusion made previously that flat-plate collectors are adequate for applications where the temperature rise above ambient is less than about 50ºC (90ºF). An exception to this conclusion is the evacuated-tube collector, which appears to be operable at twice that temperature rise. However, there are few high-temperature applications of the evacuated-tube collector to confirm their reliability at these temperatures.

6.3.4 Comparison with Parabolic Troughs

Treadwell (1979) used TMY (Typical Meteorological Year) weather data to compare the long-term performance of flat-plate collectors with parabolic trough collectors to determine at what collector operating temperature the parabolic trough collects more energy than the flat-plate collector on an annual basis.

A field of single glazed flat-plate collectors with selective absorber surfaces was compared with a field of commercial parabolic trough concentrators. Both horizontal and latitude-tilt south-facing orientations for the flat-plate collectors were considered, and both north-south and east-west tracking axis orientations were considered for the parabolic trough collectors. Typical Meteorological year (TMY) solar radiation data were used from the 26 original SOLMET sites.

It was found that the amount of diffuse energy collected by flat-plate collectors in most regions of the contiguous United States was not sufficient to compensate for the tracking capability of the troughs. Also that the typically higher optical efficiency of the flat-plate collector compensates only partially for the higher thermal efficiency of the concentrators. Over a full year’s operation, the north-south trough orientation and the latitude-tilt flat-plate orientations provided the most energy. It was also found that for a 71ºC (168ºF) demand, flat-plate collectors outperform troughs only in Florida and southern Louisiana.

The break-even temperatures for the most efficient configurations (north south troughs and latitude-tilt flat-plates) are shown in Figure 6.5. This figure shows that troughs and flat-plate collectors have equivalent performance at about 49ºC (120ºF) in the southwestern region, whereas flat -plates and troughs may be considered equivalent in terms of performance, for applications at 66ºC (150ºF) in most of the southeastern region.

Figure 6.5 Break-even temperature for comparison between flat-plate collectors tilted at the latitude angle and parabolic troughs with the tracking axis oriented in the north-south direction. From Treadwell (1979).

In addition to the numerous applications of flat-plate collectors for domestic hot-water heating and space heating for both homes and business, there are a number of industrial process heat applications of flat-plate collectors. Table 6.2 summarizes many of these. The information was extracted from Kutscher et al. (1982) and shows a wide variety of applications. Note that all the demand temperatures are under 100ºC (212ºF).

The Campbell Soup Company process heat system in Sacramento, California is the singular example of the use of flat-plate collectors to preheat water before it enters a field of parabolic trough concentrators. The field, shown in Figure 6.2, incorporates 371.6 m2 (4000 ft2) of flat-plate collectors connected in series to 278.7 m2 (3000 ft2) of parabolic trough concentrators. The industrial demand for this system is for 91ºC (195ºF) hot water, which is used in a can washing process.

Table 6.2. Industrial Process Heat Systems in the United States Using

Flat-Plate Collectors

|

Company |

Location |

Process Application |

Temperature (ºC) |

Area (m2) |

|

Hot- Water Systems |

||||

|

Anhauser-Busch, Inc. |

Jacksonville, FL |

Beer pasteurization |

60ª |

427 |

|

Aratex Services, Inc. |

Fresno, CA |

Heat process water |

50 -70 |

624 |

|

Berkeley Meat Co. |

S. Lake Tahoe, CA |

Sanitation |

82 |

232 |

|

Campbell Soup Co. |

Sacramento, CA |

Preheat can wash water |

91 |

372 |

|

Coca-Cola Bottling Co. |

Jackson, TN |

Bottle washing |

NAª |

881 |

|

Easco Photo |

Richmond, VA |

Film processing |

46 |

NA |

|

General Extrusion, Inc. |

Youngstown, OH |

Solution heating |

71-82ª |

409 |

|

Iris Images |

Mill Valley, CA |

Film processing |

24-38 |

59 |

|

Jhirmack Enterprises, Inc. |

Redding, CA |

Preheat boiler water |

71-93 |

622 |

|

Mary Kay Cosmetics |

Dallas, TX |

Sanitizing |

60 |

305 |

|

Riegel Textile Corp. |

LaFrance, SC |

Heat dye-beck water |

88ª |

621 |

|

Spicer Clutch (Dana) |

Auburn, IN |

Parts washing |

54 |

87 |

|

Hot-Air Systems |

||||

|

Gilroy Foods, Inc. |

Gilroy, CA |

Preheat drier air/ boiler feedwater |

90 |

553 |

|

Gold Kist, Inc. |

Decatur, AL |

Preheat drier air b |

82 |

1217 |

|

LaCour Kiln Services |

Canton, MS |

Lumber drying |

82 |

234 |

|

Lamanuzzi & Pantaleo |

Fresno, CA |

Raisin drying |

62 |

1951 |

ªEvacuated tube type

b

Water collector fluid/hot-air demand

6.5.1 Evacuated-Tube Collectors

In an attempt to design higher-performance flat-plate collectors with mass production capability, collectors are being manufactured that are made from glass tubes with the enclosed space sealed and evacuated. Called evacuated-tube collectors, these have very low overall heat loss when operated at high temperatures. This is because they are essentially single glazed collectors with the space between the glazing and absorber evacuated, thereby eliminating convective loss. This leaves re-radiation as the only major loss mechanism. The results of this low heat loss can be seen in the exceptional high-temperature, low-solar irradiance performance of this collector design (Figure 6.4).

Figure 6.6 shows two evacuated-tube designs. In Corning Glass Company’s design, a flat absorber plate with an attached water tube is sealed into a glass tube that is then evacuated. Solar energy is absorbed on the absorber plate and is extracted by water or other heat-transfer fluid flowing through the attached tube.

Figure 6.6 Designs of evacuated-tube collectors. Tubes are normally 5-10 cm (2-4 in.) in diameter.

In the Owens-Illinois design, concentric glass tubes are used with the inner tube surface becoming the absorber by coating it with a selective absorbing coating. The space between these tubes is evacuated. Heat-transfer fluid flows in through a third, inner, concentric feeder tube and flows out in the annulus outside the feeder tube in contact with the absorber tube surface.

The evacuated tube collector has the potential for developing high efficiencies at high temperatures. However, as a result of degradation of elastomeric seals, differential thermal expansion, and coating limitations, these collectors are limited to temperatures considerably below their maximum potential at noontime isolation levels. This means not only that applications cannot be planned for temperatures beyond these temperature limits, but also that under stagnation conditions (no heat removal

It appears that the least expensive type of solar collector is a large solar pond. However, they have been considered primarily for large industrial applications because their cost decreases considerably with increases in size. There are two basic types of solar ponds: the shallow pond and the salt-gradient pond. Both are equivalent to horizontal flat-plate collectors, since they are non-concentrating, accept both direct and diffuse solar energy, and are limited to low temperature applications.

Shallow Ponds. A shallow solar pond consists of a group of collectors made of black plastic liners lying on top of insulation that has been laid on flat graded ground. Above the water bag is at least one translucent cover sheet, supported by side curbs. When there is adequate sunshine, water is pumped into the collectors from an underground storage tank. The water inside the collectors is heated by solar radiation absorbed by the pond liner and can attain temperatures of up to 60ºC (140ºF). Once heated, the water in the collectors may be pumped to an industrial demand or a hot storage tank for later use. At night or during periods of low solar irradiance, the water in the collectors may be drained back into the underground tank, thereby conserving the heat collected. A design guide for shallow ponds has been prepared by Casamajor and Parsons (1979).

Figure 6.7 shows a shallow pond collector design proposed by Dickenson et al. (1976) for use in a low-temperature solar thermal power system. The collector modules are 4 m (14 ft) wide and 200 m (656 ft) long. The width was determined by the width of commercially available unseamed, weatherable plastic sheets.

Figure 6.7 A shallow solar pond collector. Modules are 4 m

×200 m (13 ft × 656 ft). From Dickenson et al. (1976).Salt-Gradient Ponds

. When an open body of water absorbs solar energy, convection currents are created. As the sunrays that pass through the surface layer are absorbed in lower layers, this water is heated and rises to the surface, where heat is transferred away by convection to ambient air. Once the water cools, the density increases and the surface water moves downward. This movement of water equalizes the temperature throughout the body of water.A salt-gradient solar pond employs a salt concentration gradient to suppress natural convection. Heated water holds more dissolved salt than does cooler water. The salty, heated water is also heavier and thus remains at the bottom of the solar pond. Sunlight penetrating through the top layers of the pond is absorbed at the bottom and trapped by the non-convecting gradient layer, which acts as an effective thermal insulator against convection.

In practice, salt-gradient solar ponds consist of three layers, or zones: (1) a surface convecting zone of low-salinity water, typically 0.2-0.4 m (8-16 in.) thick; (2) a non-convecting or salinity-gradient zone beneath the surface zone, in which salt concentration increases with depth, typically 1.0-1.5 m (3.3-5 ft) thick; and (3) a storage zone at the bottom of the pond of uniformly high salt concentration that stores heat and is typically 1-3 m (3.3-10 ft) thick..

For utilization of the heat stored at the bottom of the pond, hot brine is drawn from the storage zone (bottom layer) of the pond and pumped through a heat exchanger and back to the bottom of the storage zone. For power production applications where a Rankine cycle is used, condenser cooling water is drawn off the top of the pond and passed through the condenser and back to the surface, where it cools.

Construction of economical solar ponds requires the availability of inexpensive, flat land; accessibility to water; and an inexpensive source of salt or brine. A typical arrangement for this process is shown in Figure 6.8.

Figure 6.8 Electrical power production concept using salt-gradient ponds.

A salt-gradient solar pond can provide heat at temperatures in excess of 90ºC (194ºF). Such a pond provides built-in thermal storage of such large volume that heat can be collected in the summer and stored for use during the winter. Pioneering work on salt-gradient solar ponds has been done in Israel. Tabor (1981) gives an extensive review of the status and problems in this field [ see also Tabor (1983)]. An extensive bibliography on the subject has been published in SERI (1981a).

The basic physical principles of salt-gradient ponds were defined by Weinberger (1964). Rabl and Nielsen (1975) subsequently presented a model that included a convective bottom layer. A computational procedure for determination of the thermal efficiency of a pond with a diffusely reflecting bottom may be found in Hull (1982) and a parametric analysis of various design considerations in Wang and Akbarzadeh (1983).

ASHRAE (1977), "Methods of Testing to Determine the thermal Performance of Solar Collectors," ASHRAE Standard 93-77, American Society for Heating, Refrigeration, and Air -Conditioning Engineering, New York.

Casamajor, A. B., and R. E. Parsons (1979), "Design Guide for Shallow Solar Ponds," Lawrence Livermore Labs Report UCRL 52385 (Rev. 1), January.

Dickenson, W. C., A. F. Clark, J. A. Day, and L. F. Wouters (1 976), "The Shallow Solar Pond Energy Conversion System," Solar Energy 18 (1), 3.

Duffie, J. A., and W. A. Beckman (1980), Solar Engineering of Thermal Processes, John Wiley & Sons, New York, 1980.

Huil, J. R. (1982), "Calculation of Solar Pond Thermal Efficiency with a Diffusely Reflecting Bottom," Solar Energy 29 (5), 385.

Kreider, J. F., and F. Kreith (1982), Solar Heating and Cooling, 2nd ed., McGraw-Hill, New York.

Kutscher, C. F., R. L. Davenport, D. A. Dougherety, R. C. Gee, P. M. Masterson, and E. K. May (1982), "Design Approaches for Solar Industrial Process Heat Systems," SERI Report SERI/ TR-253-1356, August.

Lunde, P. J. (1980), Solar Thermal Engineering, John Wiley & Sons, New York.

Rabl, A., and C. E. Nielsen (1975), "Solar Ponds for Space Heating," Solar Energy 17 (1), 1.

SERI (198la), "Solar Ponds: A Selected Bibliography," SERI Report SERI/TR-752-711, November.

SERI (1981b), "Solar Radiation Energy Resource Atlas of the United States," SERI Report SERI/SP-642-1037, October.

Smith, J. H. (1980), "Handbook of Solar Energy Data for South-Facing Surfaces in the United States," Jet Propulsion Laboratory Report DOE/JPL-1012-25, Vol. 1, January.

Tabor, H. (1981), "Solar Ponds," Solar Energy 27(3), 181.

Tabor, H. (1983), "Solar Ponds-Corrections," letter to the editor, Solar Energy 30(1).

Treadwell, G. W. (1979), "Low-Temperature Performance Comparisons of Parabolic -Trough and Flat -Plate Collectors Based on Typical Meteorological Year Data," Sandia National Labs, Report SAND78 -0965, February.

Wang, Y. F., and A. Akbarzadeh (1983), "A Parametric Study on Solar Ponds," Solar Energy 30(6), 555.

Weinberger, H. (1964), "The Physics of the Solar Ponds," Solar Energy 8(2), 45.

Window, B., and G. L. Harding (1984), "Progress in the Materials Science of All-Glass Evacuated Collectors," Solar Energy 32 (5), 609.